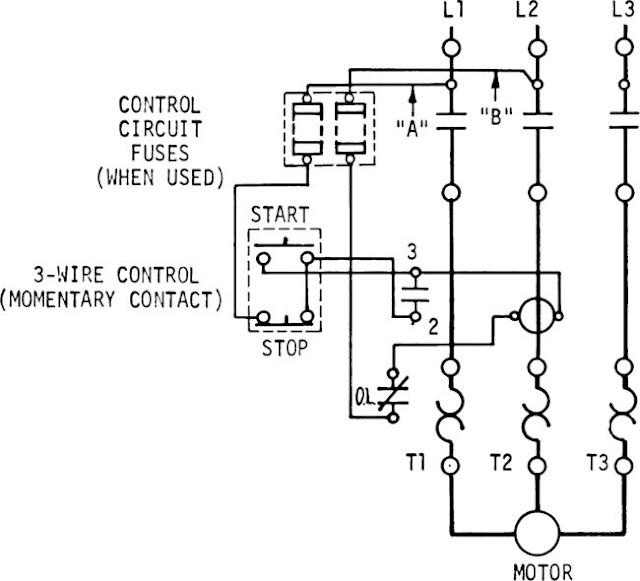

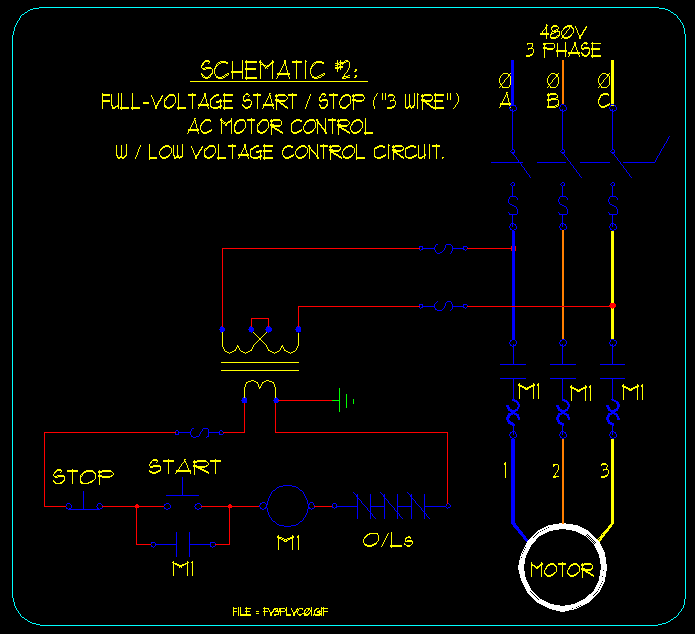

Basic Start Stop Wiring Diagram

Basic Start Stop Wiring Diagrams are essential tools for understanding and troubleshooting electrical systems in a variety of applications. These diagrams provide a visual representation of the wiring and connections between components in a start-stop circuit, making it easier to identify issues and make repairs.

Why are Basic Start Stop Wiring Diagrams essential?

- Help to understand the electrical connections in a system

- Aid in troubleshooting electrical problems

- Show the sequence of operation in a start-stop circuit

- Ensure proper installation and maintenance of equipment

How to read and interpret Basic Start Stop Wiring Diagrams effectively

When looking at a Basic Start Stop Wiring Diagram, it’s important to understand the symbols used to represent different components and how they are connected. Here are some key points to keep in mind:

- Study the legend or key to understand what each symbol represents

- Follow the flow of the circuit from start to stop to identify the sequence of operation

- Pay attention to the wiring connections and ensure they match the actual setup

- Use color coding and labeling to differentiate between wires and components

Using Basic Start Stop Wiring Diagrams for troubleshooting

Basic Start Stop Wiring Diagrams are valuable tools for troubleshooting electrical problems in a system. By referring to the diagram, you can:

- Identify faulty connections or components causing the issue

- Trace the flow of current to pinpoint where the problem lies

- Compare the actual setup with the diagram to ensure proper wiring

- Make informed decisions on repairs or replacements based on the diagram

Importance of safety when working with electrical systems

When working with electrical systems and using wiring diagrams, it’s crucial to prioritize safety to prevent accidents and injuries. Here are some safety tips and best practices to keep in mind:

- Always turn off the power before working on any electrical equipment

- Use insulated tools to avoid electric shock

- Wear appropriate personal protective equipment, such as gloves and goggles

- Follow proper lockout/tagout procedures to isolate the circuit before making any changes

Basic Start Stop Wiring Diagram

Start Stop Circuit – What They Are, Where They Are Used And How To Wire

Start Stop Wiring Diagram

Start Stop Circuit Diagram

Basic Start/Stop AC Motor Control Schematics under Repository-circuits

The Essential Guide to Start-stop Diagram – RAYPCB

Basic Start Stop Circuit Diagram